0750 445 15960770 445 16960751 445 15970751 455 1596Zyad.saddiq@yahoo.com

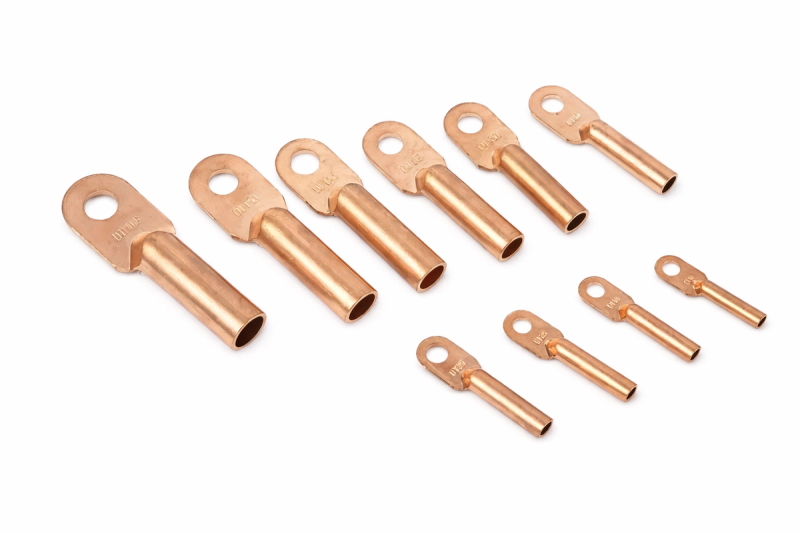

Product Report – DT Copper Cable Lugs 1. Product Name DT Copper Cable Lug (DT series copper connecting terminal) 2. Product Overview DT copper cable lugs are mechanical connectors used to terminate copper conductors and connect them to busbars, terminals, distribution boards and other electrical equipment. They provide a secure, low-resistance connection between the cable and the equipment, suitable for low- and medium-voltage power distribution, industrial control panels and general electrical installations. 3. Construction & Material - Material: high-purity electrolytic copper for excellent electrical conductivity. - Manufacturing: formed from seamless copper tube with a closed barrel to protect the conductor. - Surface: supplied as bare copper or electro-tinned for corrosion resistance. - Marking: cable cross-section (e.g. DT-10, DT-16, etc.) is stamped for identification. 4. Typical Size Range Available for cable cross-sections from 10 mm² to 300 mm². Eye hole diameters typically range between 6 mm and 20 mm. Common sizes: DT-10, DT-16, DT-25, DT-35, DT-50, DT-70, DT-95, DT-120, DT-150, DT-185, DT-240, DT-300 5. Main Features - High conductivity due to pure copper body. - Strong mechanical performance and vibration resistance. - Tin-plated versions provide corrosion resistance. - Easy installation using crimping tools. 6. Typical Applications - Power distribution boards and switchgear. - Transformer, motor, and busbar connections. - Industrial and commercial electrical installations. 7. Installation Guidelines 1. Choose correct lug size matching cable cross-section. 2. Strip insulation without damaging strands. 3. Insert conductor fully into barrel. 4. Crimp with appropriate die and pressure. 5. Inspect crimp quality after completion. 8. Quality & Standards DT copper lugs are commonly manufactured according to IEC 61238-1 and relevant national standards to ensure electrical and mechanical performance.